Harken and the challenge of the Volvo Ocean Race

by Mark Jardine, Sail-World.com 4 Jul 2018 00:00 UTC

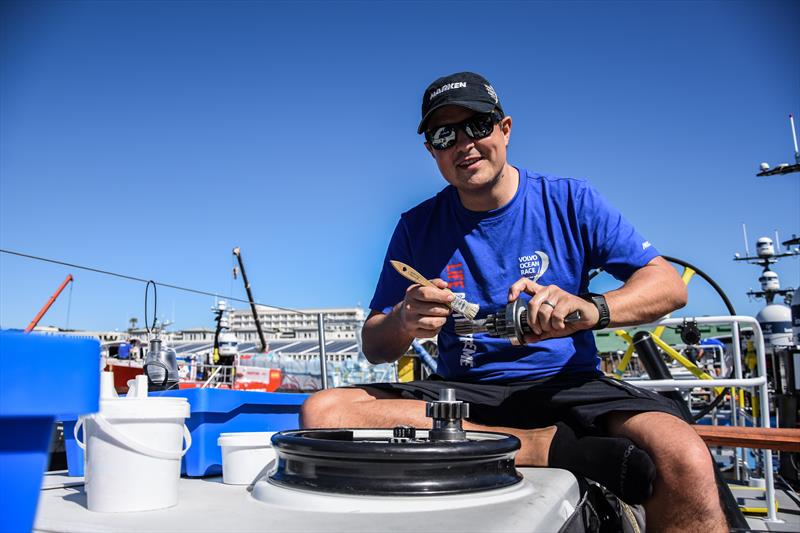

The Harken team servicing the Volvo Ocean Race yachts in Cape Town © Hannah Cotterell Media

Harken are the Official Supplier of Deck Hardware for the Volvo Ocean Race and ensure that the fleet is supplied with the very best and most reliable equipment for the duration of the event. We spoke to Mark Gardner, Custom Projects and Service Manager at Harken, during the Cardiff stopover to find out more...

Sail-World.com: What does your job entail when the boats get ashore?

Mark: The most difficult part for us is the consistency, ensuring that the service is right for every boat, so we split it up, looking at the number of miles that the boats do at different stopovers. You can really compare it to car servicing, providing differing levels of service depending on the number of miles covered. We have A+, A, B and C services, where an A+ service happens ahead of the race during the refit and assembly period in Lisbon, and it also happens again in Auckland, which is basically half way through the race.

This A+ service including taking all the winches, all the pedestal systems, the drive shafts and gear boxes off the boat, back into the container, to be serviced, cleaned and inspected before being put back on. Everything consumable being changed out – proactively servicing to get to anything before we have any problems – all the pawl springs, washers, seals will be changed out.

An A service won't have so many parts changed out and we'll inspect the gearboxes on board, unless we see something that might be a problem. In Cardiff we performed an A service.

Sail-World.com: During a stopover is it a challenge on time to get it all done for the seven teams?

Mark: Very much so - we only had five days in Cardiff. During the Volvo Ocean Race 2014-15 it was our first time with The Boatyard and that was very challenging, but this time it's easier as we know what we're expecting. I have a formula for how long we've got and how many people it will require to get the work done in the allocated amount of time. The problem for us is the time the boats leave on the next leg never changes, but the time the boats get to a stopover is variable. I'm constantly in contact with Neil Cox and Nick Bice in The Boatyard to look at the ETAs, making a call quite close to the end of the leg, saying, "We have this amount of time; this is how many people we'll need."

At times it's really challenging. Brazil was probably the biggest challenge in this race as two yachts came in very late. The timescale was to lift the boats out and put them back in the water 30 hours later. From our point of view this was very difficult as the winches are needed to lift the boats out to balance the boat, then the structural team had a look at the boats to check they were happy with that and during this process they might need to lift the boats to move them in the cradle, again requiring the winches, so we had to do two days work overnight, starting at 6pm and finishing at 4am.

Sail-World.com: So, with these time constraints, while the winners are on the stage popping the champagne, you're there stripping the boats down.

Mark: As soon as it hits the cradle, we're there with our blue buckets, each bucket is labelled with a respective winch and all the parts go straight in there together with a report card. These then go off the boat, into the container for servicing. The processes we've devised and the efficiency we now have make this possible.

Sail-World.com: The Volvo 65 is a powerful yacht. What are the areas that you're seeing the highest loads and potential problems?

Mark: The mainsheet winch is the one that gets worked hardest and these gear sets have mostly been around the world twice. With the amount of water coming over the boat - the so called 'fire hydrant conditions' – it rubs grease off over time, so you'll always get galling (adhesive wear) and plastic deformation (where the metal starts being pushed outwards), which is due to the extreme loads. The mainsheet is working all the time and is right in the middle of the boat so gets water on it all the time, so that's where we see the most damage. We haven't had any major failures during this race, but that's due to our proactive approach to maintenance.

Sail-World.com: With The Boatyard moving from port to port, you're effectively taking an entire workshop to each port and setting up. What was it like when you first set this up during the 2014-15 race?

Mark: Learning how this was going to be done during the last race was the hardest job I've ever had. I spent close to six months before the last race going through the entire inventory, working out what spares we need, how we were going to manage maintenance, the container and workshop layout. The biggest problem was working out what spares we'd need and what level we would go to. In a container set we basically have three full sets of every element of a winch and if there's a massive problem then we have a whole winch we can bolt back on.

We also have two container sets which are identical as the freight can't keep up with the stopovers. We need to make sure that when you open a drawer looking for a tool in one, it's in exactly the same place in the other container. It was a huge challenge working it out.

The other major challenge is how we report back to the teams. We have the consistency with the service, but they need to know exactly what's going on with their boat. So, I have a report which is a nice, simple checklist and that does two jobs. It's a checklist for the technician and means the shore manager and boat captain know exactly what has happened at each stopover.

We give each item a green, amber or red status depending on whether it's fine, has some wear, or has been changed out, and this gives the teams a quick reference for the shore managers. This history of maintenance is then taken back to the factory, so we can look at any components that might need redesigning or making more durable.

Sail-World.com: Have you found any of the teams are harder on the equipment than others?

Mark: Yes, definitely! I won't name names, but you can see the different sailing styles. This race has been harder on the equipment than the last race due to the new sail wardrobe, carrying three headsails at the same time, and the runner loads are going up accordingly.

Sail-World.com: The Volvo Ocean Race is at a crossroads right now. What would you like to see for the future of the race?

Mark: The one-design 65-footer is a great concept, and seeing these super-close finishes is amazing. Seeing finishes where the difference is a couple of hundred yards after 16 days at sea, such as when coming in to Newport, is spectacular. It would be nice to keep the one-design concept, maybe with a slightly faster, more exciting boat to keep people engaged. The IMOCA route is interesting, but bringing the number of crew down is not ideal.

Sail-World.com: Many thanks indeed for your time and insight.

Mark: My pleasure.

Find out more at www.harken.com.au